Rotary Cleaner (Threaded and Bolted)

Technical Data

▪ Weight: As per specification

▪ Lubrication by the cleaner itself.

▪ Working pressure: 1-3Bar

▪ Max. working temperature: 95℃

▪ Max. ambient temperature: 140℃

▪ Moist radius: Max.3M

▪ Inject cleaning radius: Max. effective radius 2M

▪ Connection: Welded, clamped, threaded

Material

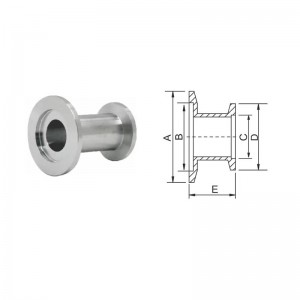

▪ Ferrule: 304/316L

▪ Sprayer: 304/316L

Operating Principles

▪ Rotary cleaning ball: The cleaning solution make the sprayer rotary by it’s motive power, then the fun jet created the whole tank and reactor with vortex. In that way, clean the remains of vessel surface effectively, reach the function of cleaning.

▪ Fixed cleaning ball: The cleaning ball is through the sprayer small hole, create the injection all around. In that way, clean the remains of vessel surface effectively, reach the function of cleaning.

Design Standard

▪ Yodsn have the standard of cleaning ball series as follows: DIN, 3A, SMS, ISO/IDF

| ST-V1120 Technical parameter |

Threaded |

||||

| Size i |

A | H | Pressure(bar) | Cleaningradius(m) | Fluxationm3/h |

|

1″ |

118 |

165 |

1.5~2.0 |

2.0~3.o |

23 |

|

1 1/4~1 1/2″ |

142 |

189 |

1.8~2.5 |

2.5~3.0 |

38 |

|

2” |

145 |

191 |

2.5~3.0 |

3.5~4.0 |

60 |

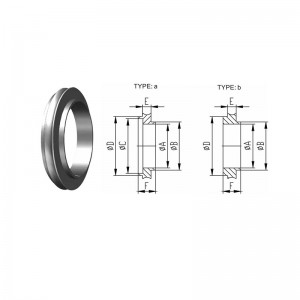

| ST-V1121 Technical parameter |

Bolted |

||||

|

Size |

A |

H |

Pressure |

Cleaning |

Fluxation |

|

1″ |

118 |

175 |

1.5~2.0 |

2.0~3.0 |

23 |

|

1 1/4~1 1/2″ |

142 |

200 |

1.8~2.5 |

2.5~3.0 |

38 |

|

2″ |

145 |

205 |

2.5~3.0 |

3.5~4.0 |

60 |

Product Detail

A drum rotary cleaner relates to the technical field of cleaning equipment, which comprises a water inlet plate, a shaft sleeve, a water inlet shaft rod, a connecting column, a Water Inlet, a nozzle, a positioning hole and a positioning column, a shaft sleeve is arranged in the water inlet plate, and a water inlet shaft rod is connected in the shaft sleeve. A connecting column with a hollow structure is arranged at the bottom of the water inlet shaft rod, and the connecting column is connected with a nozzle, the connecting column and the nozzle joint are provided with a positioning hole which penetrates each other, and the positioning column is detachable and connected with the positioning hole, the installation of the nozzle is more stable, even in high-speed rotation, the nozzle will not be thrown out of the connecting column, the structure is stable.