Sanitary Clamp Diaphragm Valve

Operating Principles

● The dlaphragm provids the body seal as well as the seat seal. There are no paths to the outside environment so it suitable for aseptic processes, When the vave is closed a pressure pad which supports the dlaphragm moves towards the salig face on the body.

When the pressure platle moves the dlaphragm flexes and is forced down onto the seat area in the centre of the body thus closing off the flow path through the body.

● The inter relation ship of body to the pressure plate prevents over compression of the diaphragm.

● The valve can be actuated either manually or pneumaically Cortolled by control tops o solenold valves.

Cetificates

● AII synthetic resin and additive are comply with FDA, certification

● Material chemical composition,physical properties anl manufacturing process are documented

● All diaphragm seal consistency with FDA certficate

-21-CFR-FDA177.1550 perfluorocarbon synthetic resin

-21-CFR-FDA-177 .2600 rubber

● USP 28 class VI CHAPTER 87 IN VITON and CHAPTER

● 88 IN-VITON consistency the authentication

● 3-A consilstency the authentication

● EN 10204 -3.1

● Domestic hygiene license

● CE-PED/97/23/EC

Relations Between Flow Rate And O.d

● KV is a data of the flow rate. The data describes valve flux when the water of 5 C to 30°C in the pressure difference for 1 bar

● KV data is the valve flow open

● Surface polishing

● Ra=roughness

● Average roughness Ra data is used as a measure of valve body surface finish of a parameter

● LT5.6mm length/measurement Lc0.8mm for five measuring

● Roughness obtained average roughness Ra data

● According ASME BPE table to classified

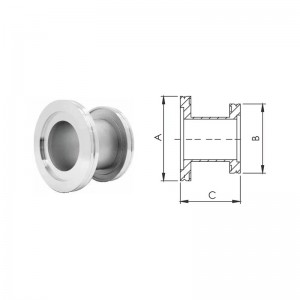

| ST-V1070 |

Clamped Diaphrag valve |

||

|

Size |

A |

B |

T |

|

DN20 |

117 |

19.1 |

1.65 |

|

DN25 |

127 |

25.4 |

1.65 |

|

DN32 |

159 |

31.8 |

1.65 |

|

DN40 |

159 |

38.1 |

1.65 |

|

DN50 |

19o |

50.8 |

1.65 |

|

DN65 |

216 |

63.5 |

1.65 |

|

DN80 |

240 |

76.2 |

2.11 |

|

DN100 |

310 |

101.6 |

2.11 |